Siyakwamukela ku-CHUANGRONG

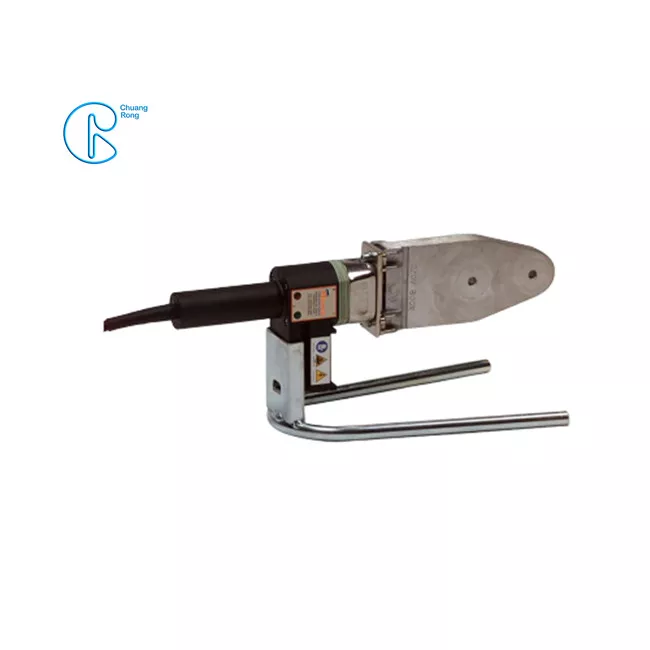

20-32mm Poly Pipe Socket Fusion Machine Handle Small PPR Welding Machine

Ulwazi Oluyisisekelo

| Inombolo yemodeli: | R32 mm | I-Max Diameter: | 32 mm |

|---|---|---|---|

| Amandla Amuncwa: | 800W | Ubukhulu: | 175*50*360mm |

| Izinga Lokushisa Lokusebenza: | Tfe:260oc(+/-10oc);Te:180oc~290oc | Iphakheji Yezokuthutha: | Ibhokisi Lepulasitiki |

Incazelo Yomkhiqizo

Ama-welders e-manual soket we-jointing pipe kanye nokufakwa, ngokuhambisana nezilinganiso ezisebenzayo. Zifaka ipuleti lokufudumeza i-aluminium kanye nesibambo sepulasitiki esisebenza ngokushisisa. Angakwazi ukushisela i-HDPE, PP, PPR, PVDF amapayipi namafitngs, futhi abonakala ngezindlela ezihlukene nezigaba zokusebenza, ezifanele izinhlelo zokusebenza ezahlukene. Atholakala nge-eletronic themmoregulator(TE) elungisekayo, noma nge-thermostat ye-electronic engaguquki (TFE).

Imininingwane yomshini wokushisela we-PPR

| Okubalulekile | I-PE, PP, PP-R, PVDF | ||

| I-Max Diameter | 32 mm | ||

| Amandla Amuncwa | 800W | ||

| Isisindo | 1.82 kg | ||

| Ubukhulu | 175*50*360mm | ||

| Izinga lokushisa lokusebenza | TFE:260ºC(+/-10ºC);TE:180ºC~290ºC | ||

| Izinga lokushisa le-ambient | -5 ~ 40ºC | ||

| Ukunikezwa kwamandla kagesi | TE:230V-Isigaba esisodwa 50/60Hz;TFE:110~230V Isigaba esisodwa 50/60 Hz | ||

IMIYALELO YOKUSEBENZA

4.1. Hlola ukuthi i-voltage ye-mains iyafana yini

I-voltage eshiwo ku-socket fusion welding

ipuleti lomshini.

4.2. AMADIVAYISI OKUSEBENZISA I-SOCKET FUSION

UMSHINI WOKUSHISA

a b

a) Imfoloko.Ifanele ukushiselwa phansi.

b) Ubakaki webhentshi. Ngomsebenzi webhentshi.

c) Inkundla. Enye indlela yemfoloko.

4.3. Faka umshini wokushisela we-socket fusion ku-

idivayisi ekhethiwe.

4.4. Faka izihlahla ze-M/F ngokwezidingo.

QAPHELA: Ubuso behlathi obuthinta umshini wokushisela kufanele buhlale buhlanzekile ngaso sonke isikhathi.

4.5. Bamba izihlahla ngokuqinile emshinini wokushisela we-Socket fusion (usebenzisa isikrufu) ukuze uthole ukushintshana kokushisa okudingekayo kwezinga lokushisa.

edingekayo ezihlahleni

A: Isikrufu esinehexagonal

B: Phina iyunithi yezihlahla

4.6. Xhuma phakathi kwamapayipi amakhulu

4.6.1. AMAmodeli we-TE

|

| Bonisa i-LO v ngemva kokuvula amandla.Ngemuva kwemizuzu eyi-10-20, ipuleti lokushisa liqala ukukhombisa izinga lokushisa, lifinyelele izinga lokushisa elibekiwe bese lizinzisaCindezela ukhiye wokusetha ukuze ufake imodi yokufudumeza bese usetha izinga lokushisa ngokwe- + -.Cindezela - ukuze ushintshe imodi. |

4.7. Imizuzu eyi-10 - 15 ngemuva kokuthi umshini wokushisela we-socket fusion uvuliwe (noma kunoma yikuphi lapho usufinyelele izinga lokushisa lokusebenza).

Yonke imishini yokushisela yepulasitiki enikeziwe isethelwe ekushiseni kwehlathi okungaba ngu-260° C.

Hlola ukuthi unqenqema lwesihlahla lunjengoba luchazwe umenzi wepayipi elizoshiselwa.Sebenzisa a

i-thermometer yedijithali

Ukulungiswa kwezinga lokushisa okunembe phakathi kuka-180° C

futhi 290° C kungenzeka. Sebenzisa i-thermometer yedijithali

ukukala ngisho nokuhluka okuncane

Ukupakisha

Okunye

Thumela umlayezo wakho kithi:

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-Skype

-

Phezulu