Siyakwamukela ku-CHUANGRONG

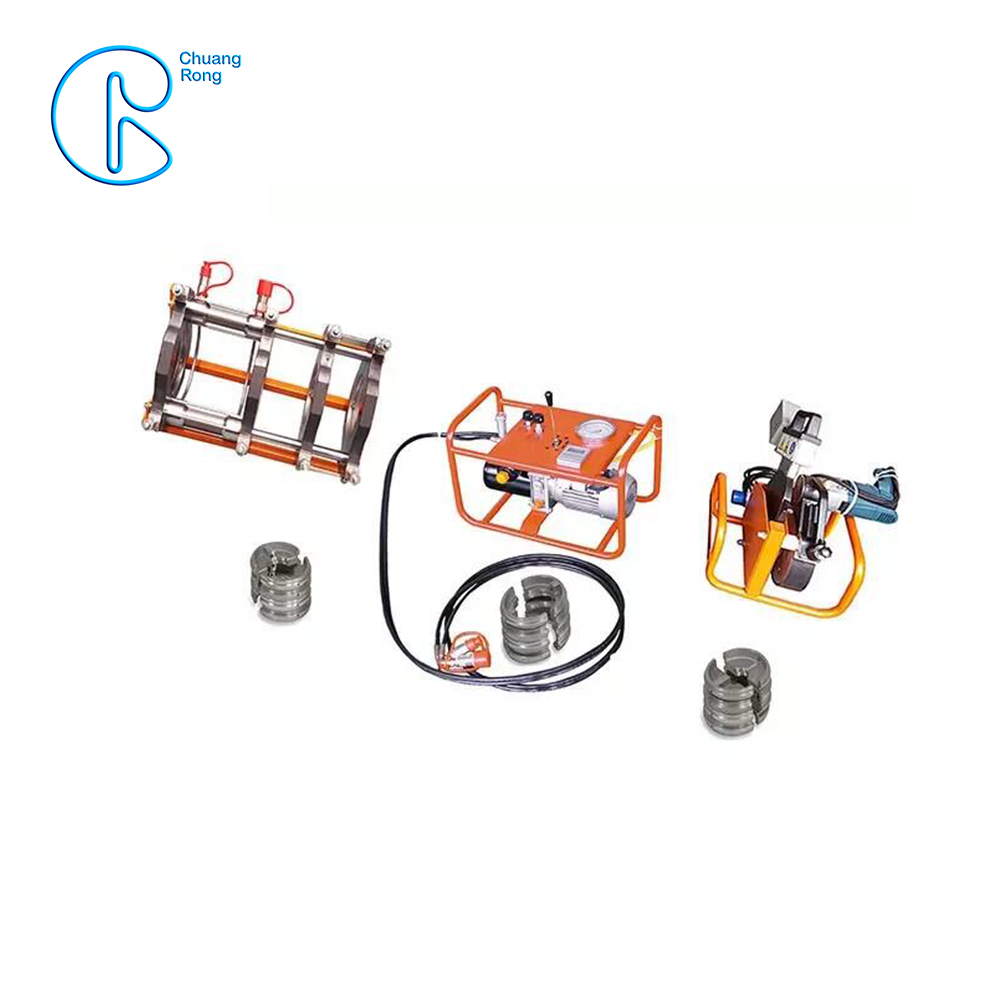

Isampula yamahhala yasefekthri I-Welping 63-250mm 4 Izimbambo ze-HDPE Pipe Manual Butt Fusion Welding Machine Umshini Wokushisela Wokufaka ugesi

Manje sinabasebenzisi abaningi abahle kakhulu bezisebenzi ezinhle kakhulu zokumaketha nge-inthanethi, i-QC, futhi sisebenza nezinhlobo zenkinga enzima ngaphakathi kwendlela yokukhiqiza yesampula Yamahhala Yefektri I-Welping 63-250mm 4 Clamps HDPE Pipe Manual Butt Fusion Welding Machine Electrofusion Welding Machine, Inhloso yethu enkulu njalo ukukleliswa njengophawu oluphezulu futhi sihole njengamaphayona endaweni yethu. Siye saqiniseka ukuthi ulwazi lwethu oluchumayo ekukhiqizeni amathuluzi luzozuza ukwethenjwa yikhasimende, Sifisa ukubambisana nokudala amandla angcono kakhulu nawe!

Manje sinabasebenzisi abaningi abasebenza kahle kakhulu be-inthanethi ukumaketha, i-QC, futhi sisebenza nezinhlobo zenkinga enzima ngaphakathi kwendlela yokukhiqizaUmshini Wokushisela Ipayipi Lepulasitiki LaseChina kanye Nomshini Wokushisela Izinqe, Sihlanganisa zonke izinzuzo zethu ukuze siqhubeke sisungula izinto ezintsha, sithuthukise futhi sithuthukise ukwakheka kwethu kwezimboni nokusebenza komkhiqizo. Sizohlala sikholelwa kukho futhi sisebenzela kukho. Siyakwamukela ukujoyina nathi ukuze sikhuthaze ukukhanya okuluhlaza, sisonke sizokwenza ikusasa elingcono!

Ulwazi lomkhiqizo

●Amandla okushisela: 3.5KW, 2.2KW ahlangabezana kuphela nokufakwa kwamandla kagesi wesigaba esisodwa esingu-220V;

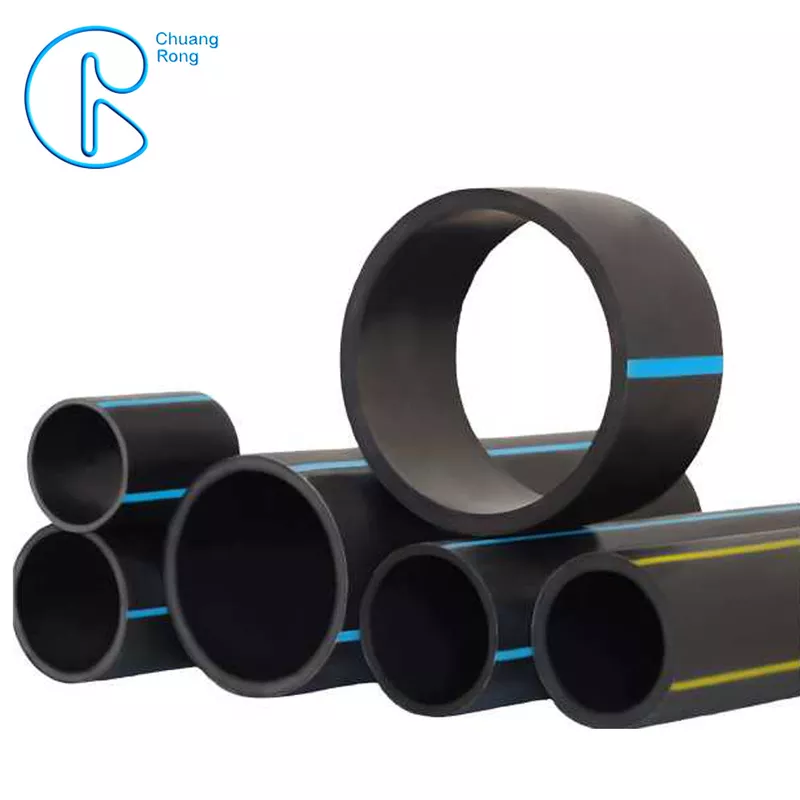

● Izinsiza ozikhethela zona: S: S: ukufunda isithwebuli; G: Indawo ye-GPS; P: iphrinta;

Qaphela: Ukugcwaliseka komsebenzi wokuskena ibhakhodi, ukuphrinta kanye ne-GPS kudingeka uthenge izesekeli ezihambisanayo.

| ◇ Iyunithi yokulawula ye-SCM ethuthukisiwe, ukulungiselelwa kwepharamitha eningi, ukulinganisa nokuvikela umsebenzi |

| ◇ Isibonisi se-LCD sokukhanya okuphezulu, ukusebenza kwesiShayina/IsiNgisi, isixhumi esibonakalayo esinobungane somuntu nomshini |

| ◇ Ukunikezwa kwamandla okubanzi nokokufaka kwamandla kagesi, kulungele ngokugcwele igagasi lenethiwekhi kagesi |

| ◇ Amandla anembile aphezulu, ukulawula isikhathi, qinisekisa ikhwalithi yokushisela |

| ◇ Isikhathi sokuphendula esiphumayo ngokushesha (500??800ms), ukuzinza okuhle lapho ukunikezwa kwamandla kunqamuka |

| ◇ Ngokusebenza kwezigaba eziyi-10 zokushisela okuhlelekayo, ezifanele izidingo zokushisela ezihlukene zokufakwa |

| ◇ Umthamo omkhulu wokugcina wedatha yokushisela, indlela elula yokufaka amapharamitha wokushisela |

| ◇ Idizayini ephelele kanye nomsebenzi wezandla wokushisela we-SMT, Yehlisa iphutha layo yonke isethi |

| ◇ Umsebenzi wokuvikela ngokumelene ne-over-current, over-voltage kanye nokugcwala njll. |

| ◇ Idizayini ehlangene, ivolumu encane nesisindo esincane |

Izici Zobuchwepheshe

| Ibanga lokusebenza | 20-200 mm |

| I-voltage ephumayo ye-Welding | 8-48V |

| Isigaba esisodwa | 230V |

| Ukunikezwa kwamandla kagesi | 50-60Hz |

| Amandla anamandla amakhulu | 4000W |

| I-Max.output yamanje | 100A |

| 60%Okukhiphayo komjikelezo womsebenzi | 60A |

| Amandla enkumbulo | 500 umbiko |

| Idigri yokuvikela | IP54 |

| Umshini wokulinganisa (WxDxH) | 263X240X300mm |

| Ikesi eliphethe ubukhulu (WxDxH) | 352x188x341 |

| Isisindo | 9Kg |

Cindezela ukhiye

| Cindezela ukhiye | Igama | Incazelo yomsebenzi |

| OK | Ukuqinisekisa | Qinisekisa |

| ESC | Phuma | Khansela |

| Ç | Khulisa | Imenyu phezulu / Idatha iyakhuphuka |

| È | Nciphisa | Imenyu phansi / Idatha iyancipha |

| Æ | Ukushintsha kwesokudla | Ukushintsha kwemenyu kwesokudla/Ishifu yesokudla yesikhundla esilungisiwe |

| Å | Ishifu yesokunxele | I-Menu left shift/Isikhundla esilungisiwe shift yesokunxele |

Ipharamitha esebenzayo

| Inombolo yemenyu. | Igama | Ibanga | Okuzenzakalelayo | Isibaluli sekhibhodi |

| Imenyu yepharamitha 1: imingcele ye-welding | ||||

| 1.01 | Ukukhethwa kwemodi yokulawula | I-voltage eqhubekayo / yamanje engaguquki | I-voltage eqhubekayo | R/W |

| 1.02 | Izigaba zokushisela | 1; 6 | 1 | |

| 1.03 | Ukumelana namapayipi | 0.00-19.99 | 0 | |

| 1.04 | Welding para. kwe-1stisigaba | 0~Kukaliwe | 0 | |

| 1.05 | Isikhathi sokushisela singu-1stisigaba | 0~9999 | 0 | |

| 1.06 | Welding para. kwe-2ndisigaba | 0~Kukaliwe | 0 | |

| 1.07 | Isikhathi sokushisela singu-2ndisigaba | 0~9999 | ||

| 0 | ||||

| 1.08 | Welding para. kwe-3rdisigaba | 0~Kukaliwe | 0 | |

| 1.09 | Isikhathi sokushisela singu-3rdisigaba | 0~9999 | 0 | |

| 1.10 | Welding para. kwe-4thisigaba | 0~Kukaliwe | 0 | |

| 1.11 | Isikhathi sokushisela singu-4thisigaba | 0~9999 | 0 | |

| 1.12 | Welding para. kwe-5thisigaba | 0~Kukaliwe | 0 | |

| 1.13 | Isikhathi sokushisela singu-5thisigaba | 0~9999 | 0 | |

| 1.14 | Welding para. kwe-6thisigaba | 0~Kukaliwe | 0 | |

| 1.15 | Isikhathi sokushisela singu-6thisigaba | 0~9999 | 0 | |

| 1.16 | Isikhathi sokupholisa | 0~9999 | 0 | |

| Ipharamitha yemenyu 2: Imingcele yokusebenza kwefomula | ||||

| 2.01 | Ifomula No. | 0~20 | 0 | R/W |

| 2.02 | Uhlobo lwepayipi lefomula | 0~32000 | 0 | |

| 2.03 | Ukumelana nepayipi lefomula | 0.00-19.99 | 0 | |

| 2.04 | Imodi yokulawula ifomula | I-voltage eqhubekayo / yamanje engaguquki | I-voltage eqhubekayo | |

| 2.05 | Izigaba ze-Formula Welding | 1; 6 | 1 | |

| 2.06 | Welding para. kwe-1stisigaba | 0~Kukaliwe | 0 | |

| 2.07 | Isikhathi sokushisela singu-1stisigaba | 0~9999 | 0 | |

| 2.08 | Welding para. kwe-2ndisigaba | 0~Kukaliwe | 0 0 | |

| 2.09 | Isikhathi sokushisela singu-2ndisigaba | 0~9999 | ||

| 0 | ||||

| 2.10 | Welding para. kwe-3rdisigaba | 0~Kukaliwe | 0 | |

| 2.11 | Isikhathi sokushisela singu-3rdisigaba | 0~9999 | 0 | |

| 2.12 | Welding para. kwe-4thisigaba | 0~Kukaliwe | 0 | |

| 2.13 | Isikhathi sokushisela singu-4thisigaba | 0~9999 | 0 | |

| 2.14 | Welding para. kwe-5thisigaba | 0~Kukaliwe | 0 | |

| 2.15 | Isikhathi sokushisela singu-5thisigaba | 0~9999 | 0 | |

| 2.16 | Welding para. kwe-6thisigaba | 0~Kukaliwe | 0 | |

| 2.17 | Isikhathi sokushisela singu-6thisigaba | 0~9999 | 0 | |

| 2.18 | Isikhathi sokupholisa sefomula | 0~9999 | 0 | |

| 2.19 | Londoloza ifomula yamanje | 0~1 | 0 | |

| Imenyu yepharamitha3: ukulungiselelwa kwamapharamitha | ||||

| 3.01 | Izinga lokushisa elijwayelekile le-ambient | 0.0℃50.0℃ | 20℃ | R/W |

| 3.02 | Isinxephezelo sezinga lokushisa elizungezile | 0.00%~0.09% | 0.02% | |

| 3.03 | Ukumisa isikhashana kokushisela kunikwe amandla | 0~1 | 0 | |

| 3.04 | Ukuhlonza ipayipi kunikwe amandla | 0~1 | 0 | |

| 3.05 | Ukusetha i-voltage ephindwe kabili | 1.0-15.0 | 10.0 | |

| 3.06 | Ukulungiselelwa kohlobo lwekhodi yebha | 0~1 | 0 | |

| 3.07 | Nika amandla ukuhlonza ukuphikisa | 0~1 | 0 | |

| 3.08 | Ibanga lokumelana | 0~±30% | ±15% | |

| 3.09 | Ulimi | 0~2 | 0 | |

| 3.10 | Unyaka | 1; 99 | 16 | |

| 3.11 | Inyanga | 1 -12 | 8 | |

| 3.12 | Usuku | 1 - 31 | 8 | |

| 3.13 | Ihora | 0;23 | 8 | |

| 3.14 | Iminithi | 0; 59 | 8 | |

| 3.15 | Isilungiselelo sasefekthri | 0~9999 | 1000 | |

| Imenyu yepharamitha 5: isethelayithi yamukelwe ipharamitha | ||||

| 5.01 | Ukulungiselelwa kwendawo yesikhathi samanje | -12+12 | 8 | R/W |

| 5.02 | Isibuyekezo sesikhathi sesathelayithi | 0~1 | 0 | |

| 5.03 | Inombolo yesathelayithi yamanje | - | - | R |

| Imenyu yepharamitha 6: ukulungiselelwa kwepharamitha yobunjiniyela | ||||

| 6.01 | Ubunjiniyela No. | Inhlanganisela yezinhlamvu ezingu-20 nezinombolo | - | R/W |

| 6.02 | Inombolo yephrojekthi. | Inhlanganisela yezinhlamvu ezingu-20 nezinombolo | - | |

| 6.03 | I-Welder No. | Inhlanganisela yezinombolo ezingu-6 | - | |

| 6.04 | I-Welding joint No. | Inhlanganisela yezinombolo ezingu-6 | - | |

| 6.05 | Uhlobo lwepayipi | Inhlanganisela yezinhlamvu eziyi-10 nezinombolo | - | |

| 6.06 | Imboni yokufakwa kwamapayipi | Inhlanganisela yezinhlamvu ezi-5 nezinombolo | - | |

| 6.07 | Ububanzi bepayipi | Inhlanganisela yezinhlamvu ezi-5 nezinombolo | - | |

| 6.08 | I-SDR yokufaka ipayipi | 33;26;21;17.6;17;13.6;11;9;Akukho | Lutho | |

| 6.09 | Izinto zamapayipi | PE80/PE100/ Akukho | Lutho | |

| 6.10 | Umshini wokushisela No. | Inhlanganisela yezinhlamvu ezingu-25 nezinombolo | - | |

Indawo yokusebenzela

Manje sinabasebenzisi abaningi abahle kakhulu bezisebenzi ezinhle kakhulu zokumaketha nge-inthanethi, i-QC, futhi sisebenza nezinhlobo zenkinga enzima ngaphakathi kwendlela yokukhiqiza yesampula Yamahhala Yefektri I-Welping 63-250mm 4 Clamps HDPE Pipe Manual Butt Fusion Welding Machine Electrofusion Welding Machine, Inhloso yethu enkulu njalo ukukleliswa njengophawu oluphezulu futhi sihole njengamaphayona endaweni yethu. Siye saqiniseka ukuthi ulwazi lwethu oluchumayo ekukhiqizeni amathuluzi luzozuza ukwethenjwa yikhasimende, Sifisa ukubambisana nokudala amandla angcono kakhulu nawe!

Manje sinabasebenzisi abaningi abahle kakhulu bezisebenzi ezinhle kakhulu zokumaketha nge-inthanethi, i-QC, futhi sisebenza nezinhlobo zenkinga enzima ngaphakathi kwendlela yokukhiqiza yesampula Yamahhala Yefektri I-Welping 63-250mm 4 Clamps HDPE Pipe Manual Butt Fusion Welding Machine Electrofusion Welding Machine, Inhloso yethu enkulu njalo ukukleliswa njengophawu oluphezulu futhi sihole njengamaphayona endaweni yethu. Siye saqiniseka ukuthi ulwazi lwethu oluchumayo ekukhiqizeni amathuluzi luzozuza ukwethenjwa yikhasimende, Sifisa ukubambisana nokudala amandla angcono kakhulu nawe!

Isampula yamahhala yasefekthriUmshini Wokushisela Ipayipi Lepulasitiki LaseChina kanye Nomshini Wokushisela Izinqe, Sihlanganisa zonke izinzuzo zethu ukuze siqhubeke sisungula izinto ezintsha, sithuthukise futhi sithuthukise ukwakheka kwethu kwezimboni nokusebenza komkhiqizo. Sizohlala sikholelwa kukho futhi sisebenzela kukho. Siyakwamukela ukujoyina nathi ukuze sikhuthaze ukukhanya okuluhlaza, sisonke sizokwenza ikusasa elingcono!

Thumela umlayezo wakho kithi:

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-Skype

-

Phezulu