Siyakwamukela ku-CHUANGRONG

160 / 250 / 315 mm I-Butt Fusion Welder Umshini Wamanzi Osebenzisa Ukushisela Ipayipi Lepulasitiki

Ulwazi Oluyisisekelo

I-CHUANGRONG iyimboni yamasheya kanye nenkampani edidiyelwe yohwebo, eyasungulwa ngo-2005 egxile ekukhiqizeniAmapayipi e-HDPE, okokufakwayo namavaluvu, amapayipi e-PPR, okokufakwayo namavaluvu, okokufaka kokuminyanisa kwe-PP namavaluvu, nokudayiswa kwemishini yokushisela yamapayipi epulasitiki, Amathuluzi Epayipi, I-Pipe Repair Clampnjalo njalo.

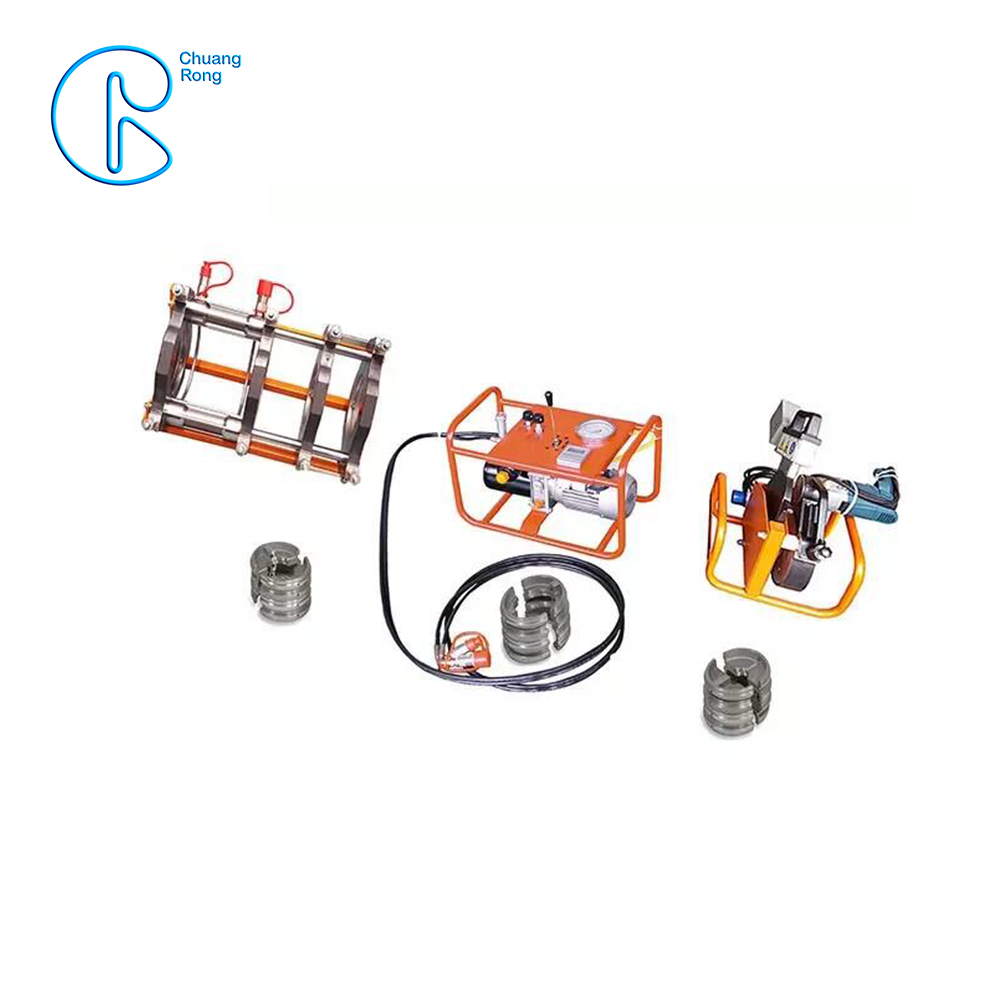

I-Butt Hydraulic Welding Machine

| Igama Lomkhiqizo: | I-Butt Fusion Welder Hydraulic Machine | I-Voltage Yokufaka: | 220VAC |

|---|---|---|---|

| Ibanga lokusebenza: | 63-160/90-250/160-315 | Ukusetshenziswa: | Amapayipi Welding |

| Isiqinisekiso: | Unyaka owodwa | Ukwakhiwa: | Umzimba Womshini,Isisiki,I-Heating Plate,Iyunithi Yokulawula Umshini Osebenza Ngamanzi,Isikhwama Samathuluzi |

Incazelo Yomkhiqizo

Umshini wokuhlanganisa we-hydraulic butt fusion oziqondanisayo, olungele ukushisela amapayipi ngaphansi kwengcindezi yamanzi, igesi nolunye uketshezi. Yakhiwe ngokuya ngezitendi zamazwe ngamazwe (UNI 10565, ISO12176-1). Kufaka phakathi:

- Umzimba womshini:eyakhiwe ngohlaka olusekelayo, izinsimbi ezine nezinsimbi ezine kanye namasilinda adonsa amanzi amabili anoxhumo olusheshayo olungaconsi.

-Ipuleti lokushisaene-thermometr eyakhelwe ngaphakathi, yokuhlola izinga lokushisa elisebenzayo, kanye ne-thermoregulator ye-elekthronikhi enembayo nesibonisi sedijithali nezinkinobho ezilawulayo. Ukwehluleka kophenyo oluncikene kuholele ekutheni izinkomba zihlole ukuthi umshini usebenza ngokuzihambela nje, ukwehluleka kophenyo okuncikene kanye/noma okudidayo okumaphakathi.

-Umsiki wokugayaukubhekana namakhanda amapayipi kanye/noma izinsimbi. Ihlanganisa i-micro-switch yokuphepha kanye ne-thermal circuit breaker.

-I-elctro-hydraulic gearcasekubangelwa ukuphahlazeka nokugqwala komkhathi ngebhokisi le-plstic. Kuhlanganisa i-lever yokulawula, ukuvula nokuvala ama-clamps, ukucindezela okukhulu kanye nama-vales okukhipha, ama-hoses oxhumano lwe-hydraulic ane-coupling esheshayo engaconsi kanye ne-timer. Umshini usethiwe ngaphambili ukuze kuxhunywe isilawuli se-elekthronikhi esifika nesikhwama sokuvikela izinga lokushisa eliphezulu, esiphinde sivikele into yokushisisa ukuthi ingaklwejwa.

Imodi iyakwazi ukushisela okokufaka njengezindololwane, ama tee, amagatsha angu-Y nama-flanges entanyeni.

I-CHUANGRONG ineqembu elihle kakhulu labasebenzi elinolwazi olucebile. Uthishanhloko wawo Ubuqotho, Ubungcweti kanye Nempumelelo. Isungule ubudlelwano bebhizinisi namazwe angaphezu kwama-80 nezindawo embonini ehlobene. Njenge-United States, Chile, Guyana, United Arab Emirates, Saudi Arabia, Indonesia, Malaysia, Bangladesh, Mongolia, Russia, Africa njalonjalo.

Siyakwamukela ukuxhumana nathi ukuze uthole imininingwane yemikhiqizo kanye nesevisi yobungcweti.

Sicela uthumele i-imeyili ku:chuangrong@cdchuangrong.com noma Ucingo:+ 86-28-84319855

| IZINGXENYE EZINGAMILE | 160 | 250 | 315 |

| 230V | 230V | 230V | |

| Ibanga lobubanzi [mm] | ngo-40¸160 | ngi 75¸250 | ngo 90¸315 |

| Izinto zokwakha | I-Polyethylene PE-HD: PE 80(MRS 8), PE 100(MRS 10), Polypropylene PP nezinye izinto zokwakha ze-thermoplastic | ||

| Ibanga lamazinga okushisa e-ambient[° C] | Ukusuka -5 kuye +40 (PE 100: kusuka ku-0 kuye +40) | ||

| Ukunikezwa kwamandla kagesi | 230VAC 50/60Hz | ||

| Ubukhulu bengqikithi yamandla amuncwa [W] | 1880 | 3080 | 4420 |

| Isigaba se-insulation | 1: umqhubi wokuvikela | ||

| Izinga lomsindo [dB (A)] | Leq=79.2 | ||

| Isisindo sisonke somshini ojwayelekile [kg] | 69 | 113 | 176 |

| UMZIMBA WOMSHINI | |||

| Ingxenye ephelele yamasilinda [cm2] | 2,498 | 5,105 | 5,890 |

| Ubukhulu W×D×H [mm] | 740'360'370 | 960'470'470 | 1090'620'590 |

| Isisindo [kg] | 27 | 54 | 100 |

| I-MILLING CUTTER | |||

| Amandla okuzisholo [W] | 800 | 800 | 1200 |

| I-Fuse | I-T5'20 3,15A 250V | I-F5'20 5A 250V | I-F5'20 5A 250V |

| Isivinini sokuzungeza [rev./min] | 109 | 75 | 87 |

| Ubukhulu W×D×H [mm] | 375'325'280 | 440'450'380 | 600'460'390 |

| Isisindo [kg] | 9 | 15 | 21 |

| I-HEATING PLATE | |||

| Ubukhulu bengqikithi yamandla amuncwa [W] | 800 | 2000 | 3000 |

| Ukulungiswa kwezinga lokushisa | 50¸320°C | ||

| Isikhathi sokufinyelela izinga lokushisa lokusebenza | < 20 min. | ||

| Ubukhulu W×D×H [mm] | 410'280'50 | 470'50'490 | 470'50'600 |

| Isisindo [kg] | 3 | 8 | 13 |

| ELECTROHYDRAULIC GEARCASE | |

| Amandla okuzisholo [W] | 370 |

| Ibanga lokucindezela [ibha] | 0¸ 150 |

| Amafutha e-hydraulic | Isigaba se-viscosity: 46 noma 68 ISO 3448 Amafutha anconyiwe: TEXACO RANDO HDZ 46, ESSO UNIVIS N 46 SHELL TELLUS T 46 |

| Ubukhulu W×D×H [mm] | 520'300'325 |

| Isisindo [kg] | 26 |

| Ilungiselelwe i-Dual Pressure welding (i-valve yokukhipha ingcindezi eyengeziwe) | |

| USEKELO LWEMILLING CUTTER / HEATING PLATE | |||

| Ubukhulu W×D×H [mm] | 290'280'275 | 380'265'600 | 590'315'650 |

| Isisindo [kg] | 4 | 10 | 16 |

9.1.AMAPHAyiphi / IZICI EZIFAKAYO

Kusebenza amafomula nezilinganiso ezilandelayo:

| I-Standard Dimension Ratio | Uchungechunge |  |  |

| I-SDR | 41 | 33 | 27, 6 | 26 | 22 | 21 | 17, 6 | 17 | 13, 6 | 11 | 9 | 7,4 | 6 |

| S | 20 | 16 | 13.3 | 12,5 | 10,5 | 10 | 8,3 | 8 | 6,3 | 5 | 4 | 3,2 | 2,5 |

|

| |||||||||||||

| I-PN (PE 80) | 3,2 | 4 | /// | 5 | 6 | /// | /// | 8 | 10 | 12,5 | 16 | 20 | 25 |

|

| |||||||||||||

| I-PN (PE 100) | 4 | 5 | 6 | /// | /// | 8 | /// | 10 | 12,5 | 16 | 20 | 25 | 32 |

|

| |||||||||||||

| I-PN (PP) | 2,5 | 3,2 | /// | 4 | /// | /// | 6 | /// | /// | 10 | 12,5 | 16 | 20 |

(Ukucindezela Okuzinzile ku-20° C)

Nalu uhlu lwamafomula asetshenziselwa ukubala imingcele yokushisela, namathebula emingcele (ngokuhambisana nemithethonqubo ehlukahlukene yobubanzi obuvamile nobukhulu bamapayipi / okokufaka).

QAPHELA 1: Inani lengcindezi esondelayoP1, elilingana nengcindezi yokushiselaP5, izosethwa ku-gearcase futhi itholwa nguenezelainani elibaliwe elihambisanayo (noma elitholwe kwelinye lalawa mathebula anikeziwe) kuya kunani lokucindezela kokudonsa (Pt) kukalwa nge-orator emshinini.

QAPHELA 2: Ngaphambi kokubonisana namathebula lapha, i-oorator kumele iqinisekise ukuthiokwangempelausayizi, njengoba kukalwa epayipini/ukufaka, empelenikuyahambisanakwezaziwa zalelo payipi/ukulinganisa. Uma kungenjalo, futhi kuphela uma kwenzeka ubukhulu bangempela bepayipi / ukulinganisa buhlonipha ukubekezelelana okulawulwayo, i-oorator kufanele ibale imingcele yokushisela ngokusebenzisa enye yamafomula anikezwe lapha. Sebenzisa i-callifor kulesi silinganiso.

QAPHELA 3: Amanani okukhulunywe ngawo asebenza endaweni yokushisela engu-20°C enezivikelo ezanele ezimweni zezulu ezimbi.

QAPHELA 4:Zonke izibalo kufanele zenziwe ngo-mm (pipe / fittingDububanzi kanyes ubukhulu).

Uma unemibuzo, ungazizwa ukhululekile ukuxhumana nathi nganoma yisiphi isikhathi.

Siyakwamukela ukuxhumana nathi ukuze uthole imininingwane yemikhiqizo kanye nesevisi yobungcweti.

Sicela uthumele i-imeyili ku: chuangrong@cdchuangrong.com noma Ucingo:+ 86-28-84319855

II-ZYRD ingumshini wokushisela osendaweni ofakwe into yokushisisa izinqe zamapayipi kanye/noma izifakelo ezenziwe nge-Polyethylene (PE), i-Polypropylene (PP) nezinye izinto ze-thermoplastic ezihloselwe ukuthwala igesi evuthayo, amanzi nolunye uketshezi ngaphansi kwengcindezi.

II-ZYRD ingashisela i-PE100 ngendlela ye-“Dual Pressure”.

Ukusetshenziswa kwalo mshini wokushisela kuvunyelwe kuphela kubasebenzi abaqeqeshiwe abaneziqu ezidingwa yimithethonqubo esebenzayo.

Uma unemibuzo, ungazizwa ukhululekile ukuxhumana nathi nganoma yisiphi isikhathi.

Siyakwamukela ukuxhumana nathi ukuze uthole imininingwane yemikhiqizo kanye nesevisi yobungcweti.

Sicela uthumele i-imeyili ku: chuangrong@cdchuangrong.com noma Ucingo:+ 86-28-84319855

Thumela umlayezo wakho kithi:

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-Skype

-

Phezulu